MEETS

PERFORMANCE

In our in-house R&D poraComp® Center, we develop our unique compounds with Poraver® or poraSpheres® as the starting material. We focus our development work on saving plastics, increasing sustainability through the use of Poraver® and/or poraSpheres®, and specifically improving properties by combining them with other additives.

The formulations are therefore constantly and flexibly optimised for the respective area of application and are very diverse due to different mixing ratios. We currently distinguish between four product families based on poraComp® compounds. What they all have in common is that they are more sustainable due to the proportion of Poraver® / poraSpheres® and thus actively contribute to the conservation of resources.

Our product families

- Polyethylene-based compounds (HDPE, LDPE, LLDPE)

- Polyamide compounds (e.g. PA6), also HFFR

- Polycarbonate blends (PC/ABS), surface modified

- Polypropylene compounds (PP compounds), also with glass fibres

poraComp® made of polypropylene, natural

poraComp® made of polypropylene, dyed

poraComp® made of polyethylene with halogen-free flame protection

poraComp® made of polyamide with halogen-free flame protection

POLYMER-GLASS-COMPOUNDS

The unique combination of Poraver®, poraSpheres® and plastics takes the best of two material worlds and creates high-quality compounds with Poraver® that are highly efficient, lightweight and preserve resources. Numerous users are already benefiting from the many advantages of the intelligent polymer-glass-compound.

We are specialists in the modification and processing of thermoplastics with our in-house products Poraver® and poraSpheres®, both made from post-consumer recycled glass.

In our development work at our modern, well-equipped Kunststoff Center, we focus on customized solutions for individual product and project requirements – and in the shortest possible time. We are guided by current trends, incorporate new ideas and take market requirements into account.

SUSTAINABLE

- Filler made from recycled material

- Saves CO2

- Conserves resources for the environment

EFFICIENT

- Up to 30% higher output rates in production due to optimized thermal and rheological properties

- Minimized longitudinal and transverse shrinkage and residual stresses

- Improved flame retardant properties

FLEXIBLE

- Reduced wear, lower heat capacity and higher service life of processing machines compared to standard fillers

- Processing on all standard lines (sheet, pipe or profile extrusion as well as injection molding and additive manufacturing)

- Dynamic and rapid adaptation of compound properties to customer and market requirements

LIGHTWEIGHT

- Significant weight reduction of components compared to standard fillers (compounds up to 40 % lighter)

- Number 1 worldwide in the production of sustainable lightweight fillers

- High availability due to in-house production

poraComp® is the clever combination of Poraver® expanded glass or poraSpheres® hollow microspheres and thermoplastics. By using our functional fillers made of resource-saving recycled glass, it provides the advantage in sustainability with unique properties.

Recycled glass (l.) and poraSpheres® or Poraver® (m.) become poraComp® (r.).

Comparison poraSpheres® and Poraver®

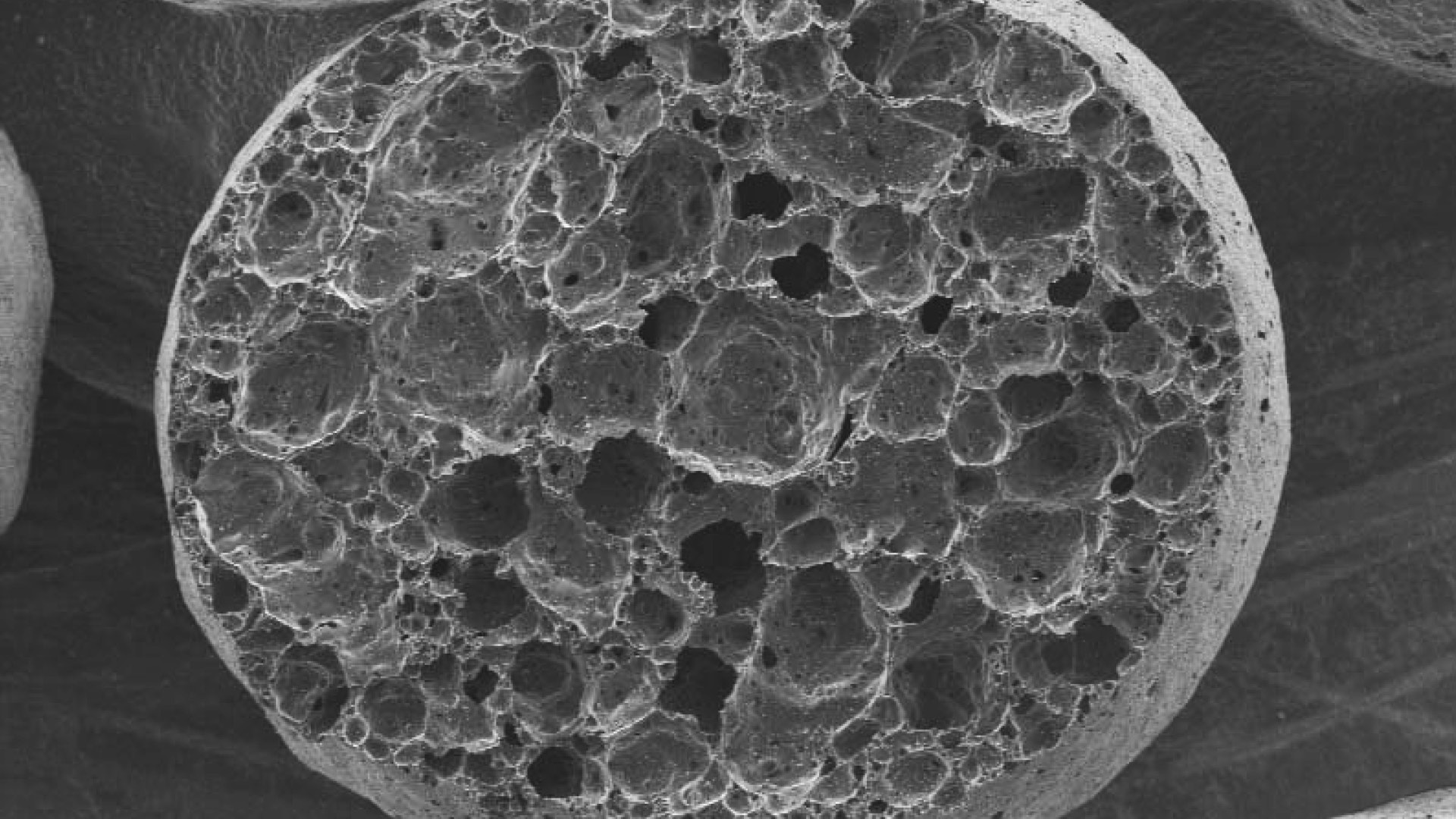

The schematic representation of a cut poraSperes® grain illustrates the structure with only one single cavity.

The image of a Poraver® grain (1-2 mm) taken with a scanning electron micro-scope shows its multicellular internal structure.

The relative global warming potential or CO2 equivalent is a measure of the relative contribution of a substance to the greenhouse effect over a certain period of time. It indicates how much a certain amount of the substance contributes to global warming compared to the same amount of CO2. For example, the CO2 equivalent for methane is 28 for a time horizon of 100 years, which means that one kilogram of methane contributes 28 times as much to the greenhouse effect within the first 100 years after its release as one kilogram of CO2. In comparison, the CO2 equivalent of Poraver® is 0,46 2).

With poraComp® you get a functional solution that significantly improves the properties and the carbon footprint of your products. By using poraComp® compounds based on polyamide, the CO2 equivalent per kilogram is reduced by 1.1 compared to non-reinforced polyamide. In comparison with glass fiber reinforced polyamide, the reduction is even higher at around 1.6 per kilogram.

Sources:

1) LCA database of environmental impacts to inform material selection process, Callum Hill, Andrew Norton JCH Industrial Ecology Ltd, DACOMAT, Horizon 2020

2) M.-M. Pang et al. / Journal of Cleaner Production 64 (2014) 602e608

3) Life cycle assessment Poraver® according to ISO 14040/44:2006 prepared by Intechnica

Consult GmbH, Nürnberg

The use of sustainable products, the avoidance of waste and the recycling of valuable materials are the focus of society and the plastics industry. Our poraComp® compounds are based on using sustainable fillers – so every kilo of poraComp® saves CO2. The product is even more sustainable when recycled materials are used – this is how we achieve almost 100% recyclate-based compounds.

Possible Applications

- Plastics with improved sustainability due to high recycled content

- High performance compounds with reduced density

- Compounds with improved flame retardancy

- Conductive plastics or other special applications

- Scratch resistant compounds for high value applications

- Applications in the construction, automotive, furniture and electrical industries, for consumer products and household appliances, dimensionally stable packaging, transport containers and many more

In addition to our range of compounds, we also offer compounds with tailor-made properties for your special application.

Your partner in the development process

In our pilot plant, we combine our knowledge of materials with production know-how and offer you the opportunity for standardized material testing. Our laboratory for mechanical testing of polymeric materials enables not only common procedures such as tensile and impact strength testing, but also complex material analyses, which are constantly being expanded and upgraded. We would be pleased to support your project with lab testing – please contact us.

Determination of mechanical properties

• Tensile properties according to DIN EN ISO 527

• 3-point bending test according to DIN EN ISO 178

• Creep behaviour according to DIN EN ISO 899

• Determination of Charpy impact properties according to DIN EN ISO 179

• Indentation hardness according to DIN EN ISO 868

• Score hardness according to VDI/VDE 2616

(Erichsen type 318)

Determination of material properties

• Bulk density according to DIN EN ISO 60

• Raw density according to DIN EN ISO 1183

• Moisture content according to DIN EN 20287

• Filler content according to DIN EN ISO 3451

• Melt mass flow rate (MFR) and melt volume flow rate (MVR) according to DIN EN ISO 1133

• Flammability test according to UL 94

• Determination of the particle size distribution by laser diffraction according to ISO 13320

• Digital microscopy

- Conserves resources and nature

- Saves up to 20 % CO2 compared to conventional compounds

- Saves up to 30 % of plastics

- Dispenses with environmentally harmful additives

- Increases the proportion of recycled material in the end product