Poraver® consists of 100 % recycled glass, is purely mineral and therefore particularly environmentally friendly. Our lightweight aggregate offers a unique mix of outstanding properties. Despite its low density, the granulate is very pressure-resistant. It not only serves as thermal insulation, but also absorbs sound, is permanently dimensionally stable and resistant to heat, cold, moisture and chemicals. The very good properties make Poraver® expanded glass a proven aggregate in lightweight concrete, tile adhesives and plaster as well as ideal as an insulating material in dry and levelling fills.

Waste glass that is not suitable for the production of new container glass is the basis for the production of Poraver®. The glass cullets are finely ground, granulated and blown in a rotary kiln. The result is a new, ecological and versatile lightweight aggregate that is used worldwide as an insulating material and raw material.

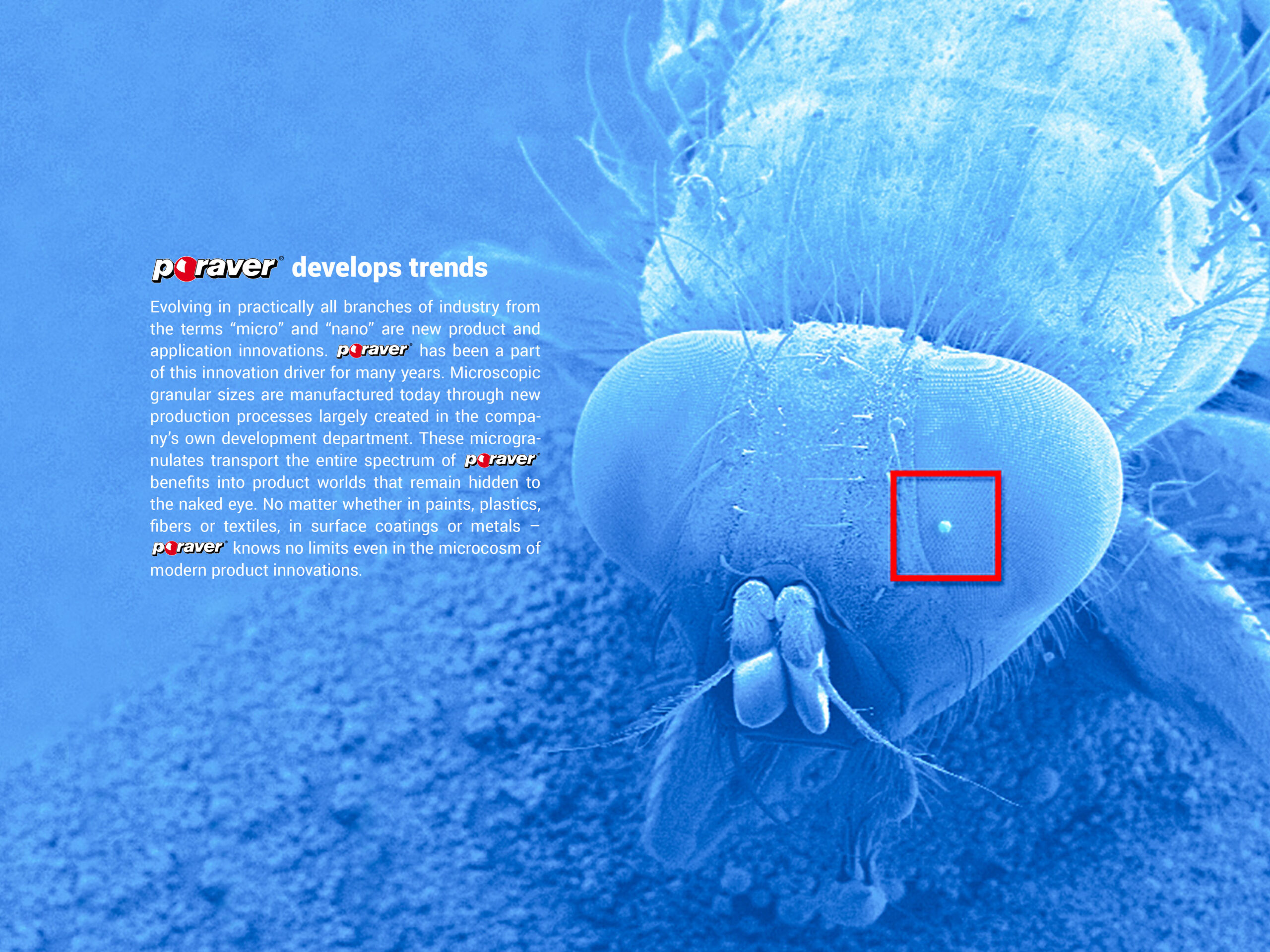

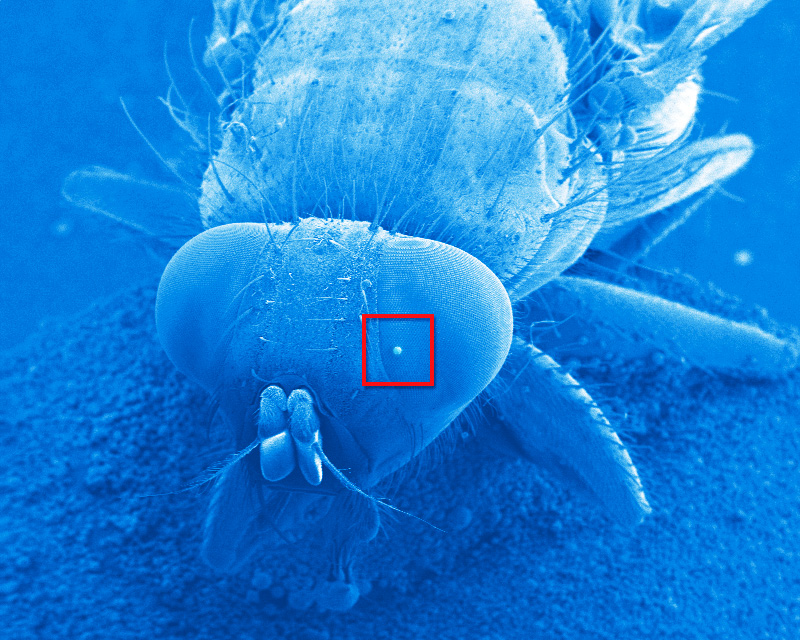

Evolving in practically all branches of indus-try from the terms “micro” and “nano” are new product and application innovations. Poraver® has been a part of this innovation driver for many years. Microscopic granular sizes are manufactured today through new production processes largely created in the company’s own development department. These microgranulates transport the entire spectrum of Poraver® benefits into product worlds that remain hidden to the naked eye. No matter whether in paints, plastics, fibers or textiles, in surface coatings or metals – Poraver® knows no limits even in the microcosm of modern product innovations.

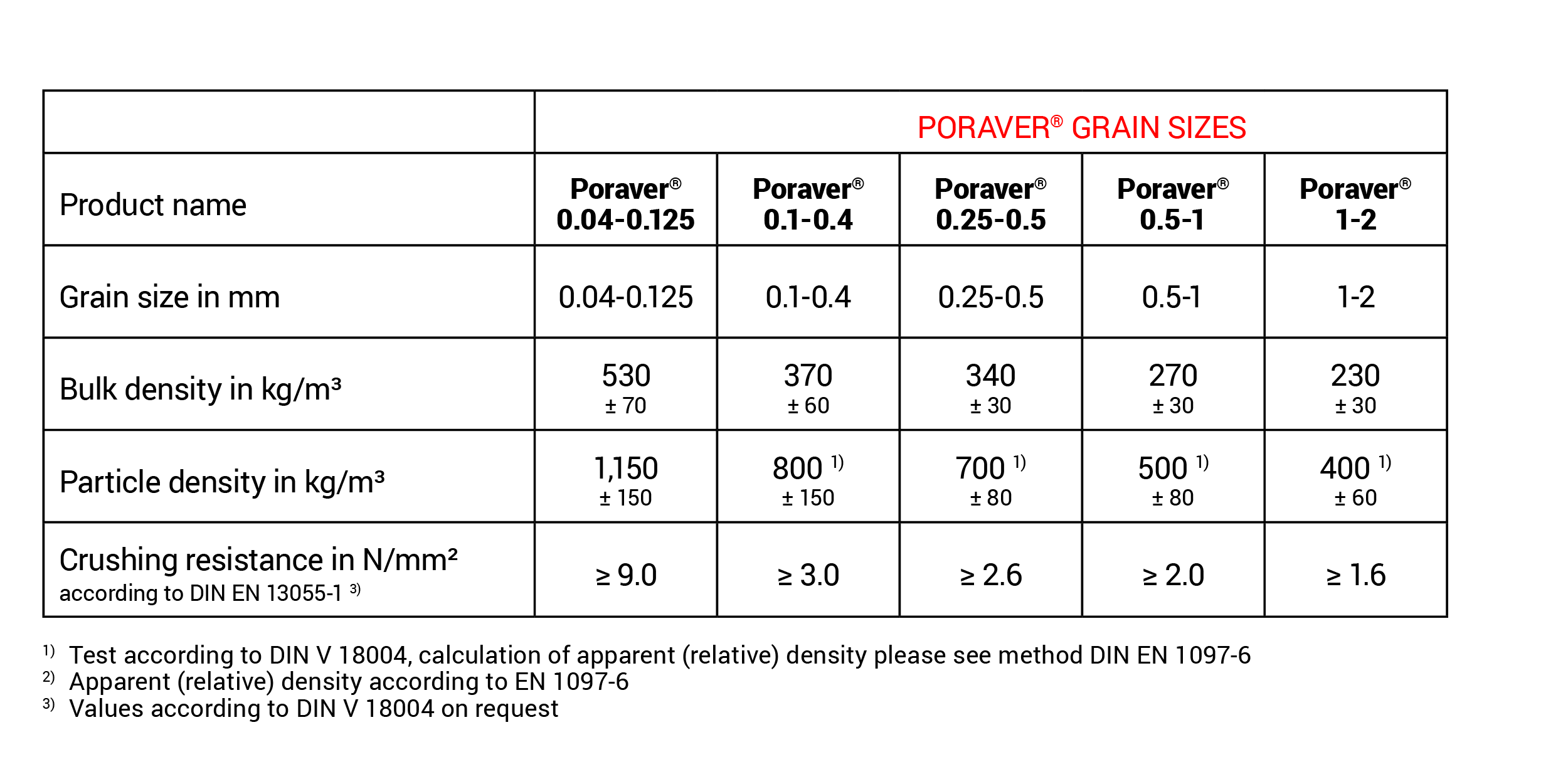

Poraver® is an industrially produced lightweight aggregate according to DIN EN 13055-1, approved for use in lightweight concrete as well as ideal for the production of mortar, bitumen-bound mixtures or for unbound and bound applications. Poraver® is monitored by the LGA according to System 2+ (except grain size 0.04-0.125). In grain size 2-4, Poraver® is approved by the DiBt as a thermal insulation fill (approval Z-23.11-114). Detailed technical data and the chemical analysis are available on request.

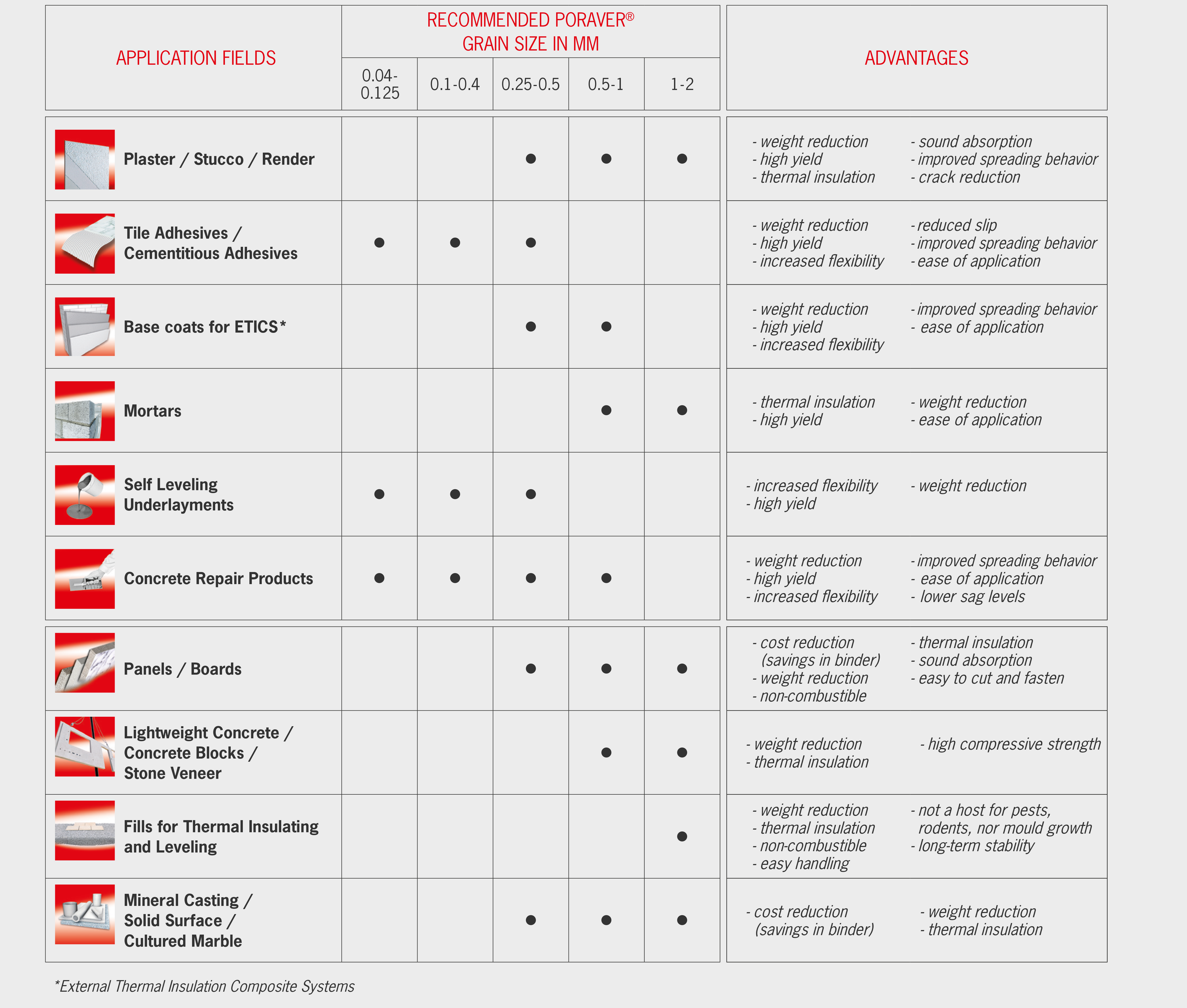

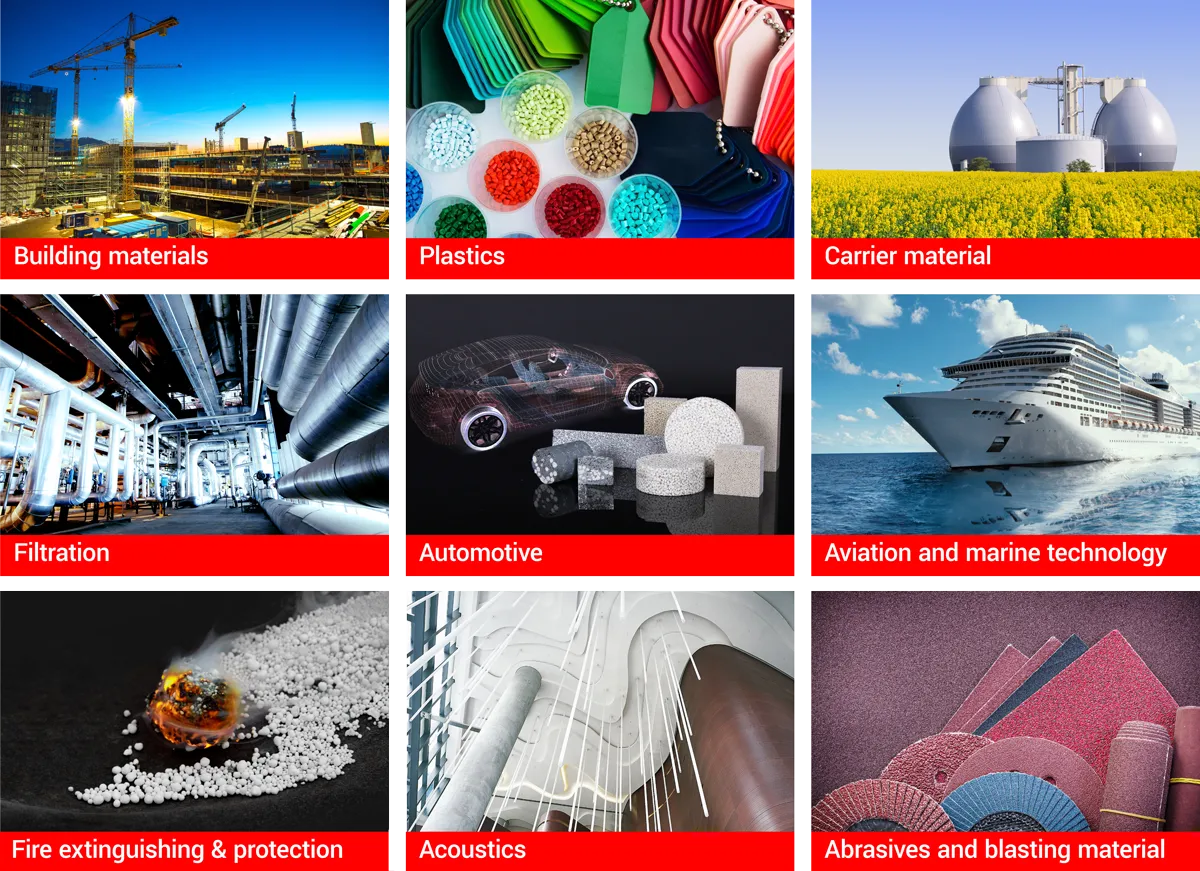

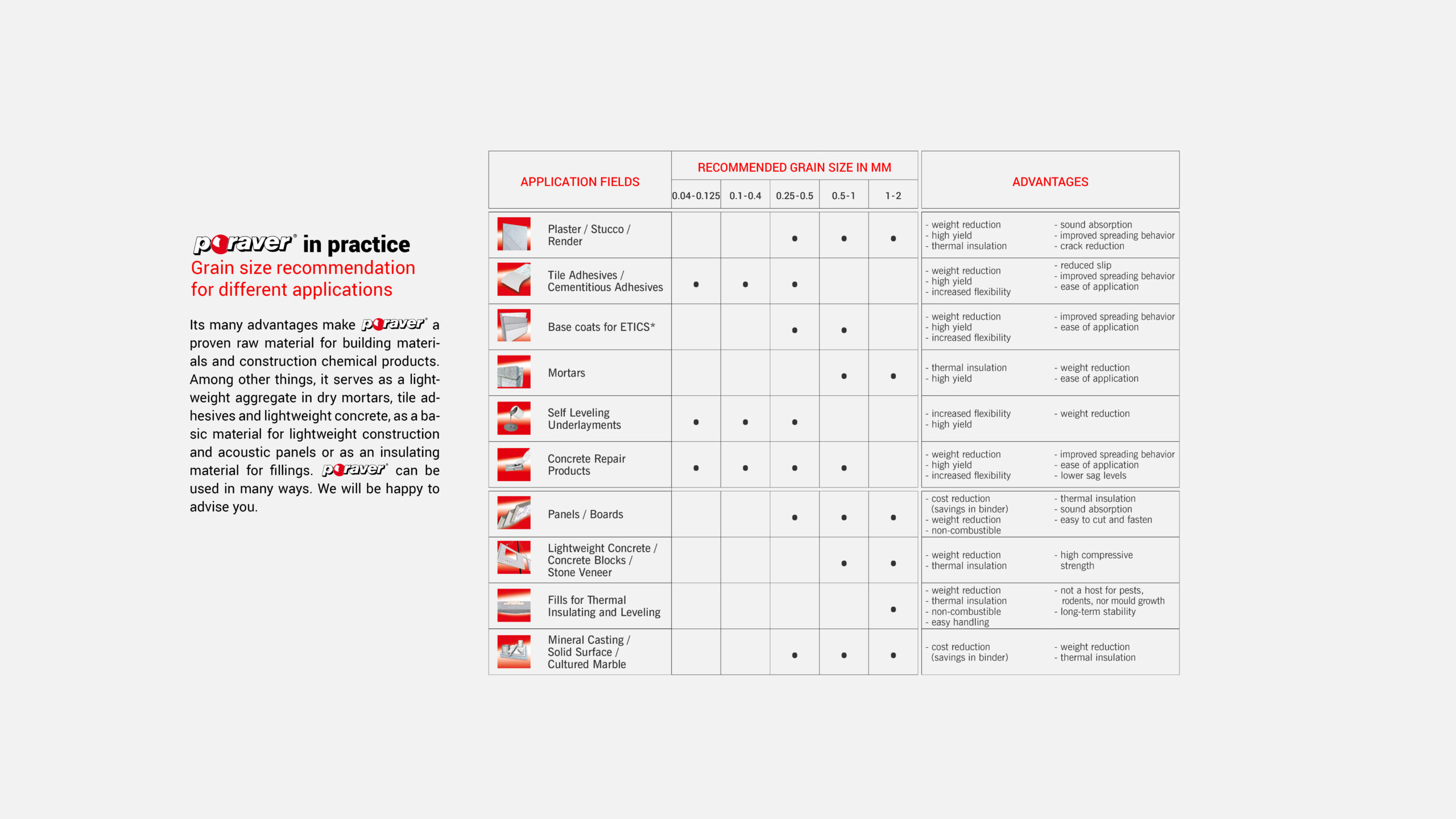

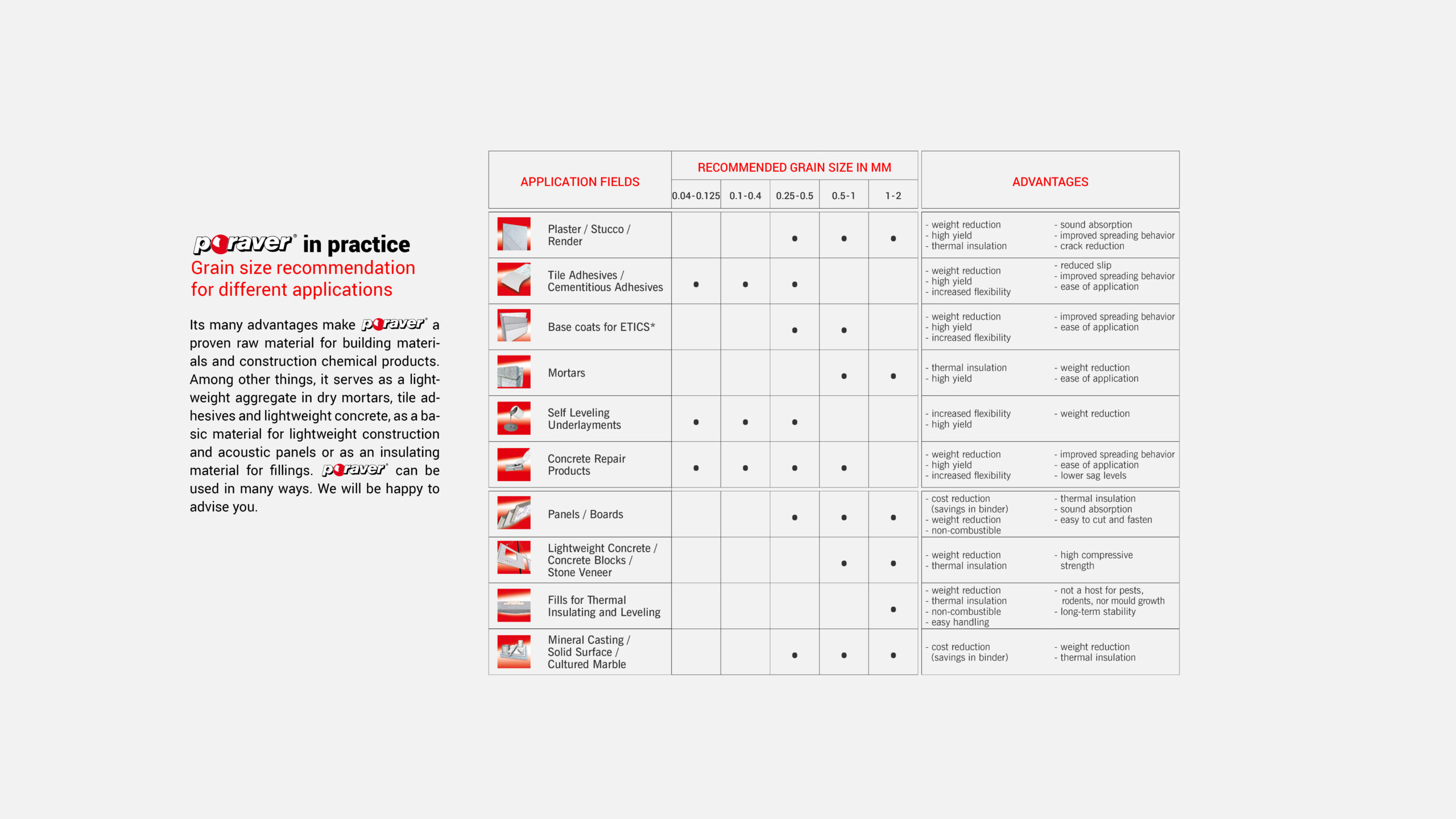

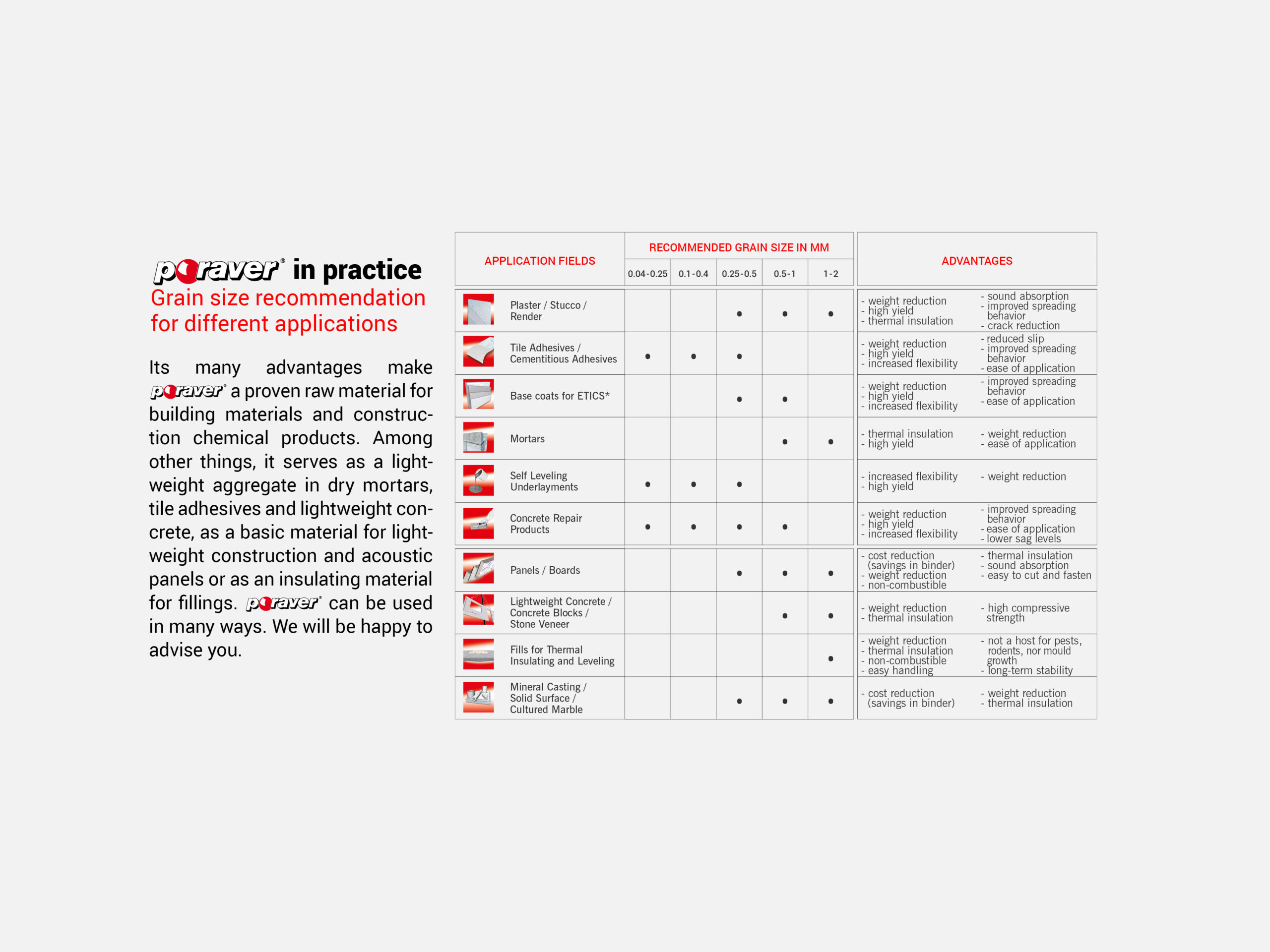

Its many advantages make Poraver® a proven raw material for building materials and construction chemical products. Among other things, it serves as a lightweight aggregate in dry mortars, tile adhesives and lightweight concrete, as a basic material for lightweight construction and acoustic panels or as an insulating material for fillings. Poraver® can be used in many ways. We will be happy to advise you.

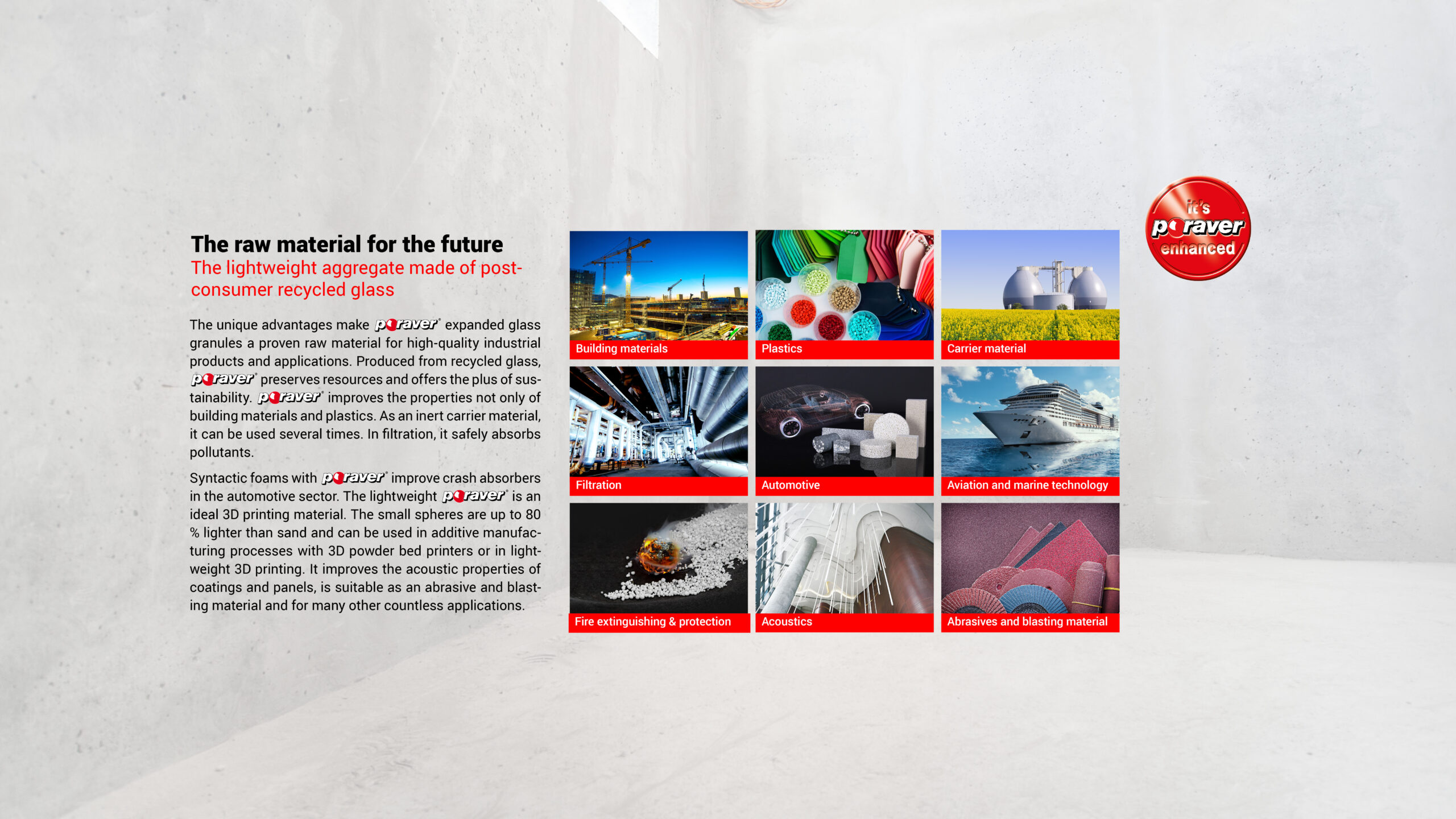

The unique advantages make Poraver® expanded glass granules versatile and a proven raw material for high-quality industrial products and applications. Produced from recycled glass, Poraver® preserves resources and offers the plus of sustainability. Poraver® improves the properties not only of building materials and plastics. As an inert carrier material, it can be used several times. In filtration, it safely absorbs pollutants. Syntactic foams with Poraver® improve crash absorbers in the automotive sector. The lightweight Poraver® expanded glass is an ideal 3D printing material. The small spheres are up to 80% lighter than sand and can be used in additive manufacturing processes with 3D powder bed printers or in lightweight 3D printing. It improves the acoustic properties of coatings and panels, is suitable as an abrasive and blasting material and for many other countless applications.

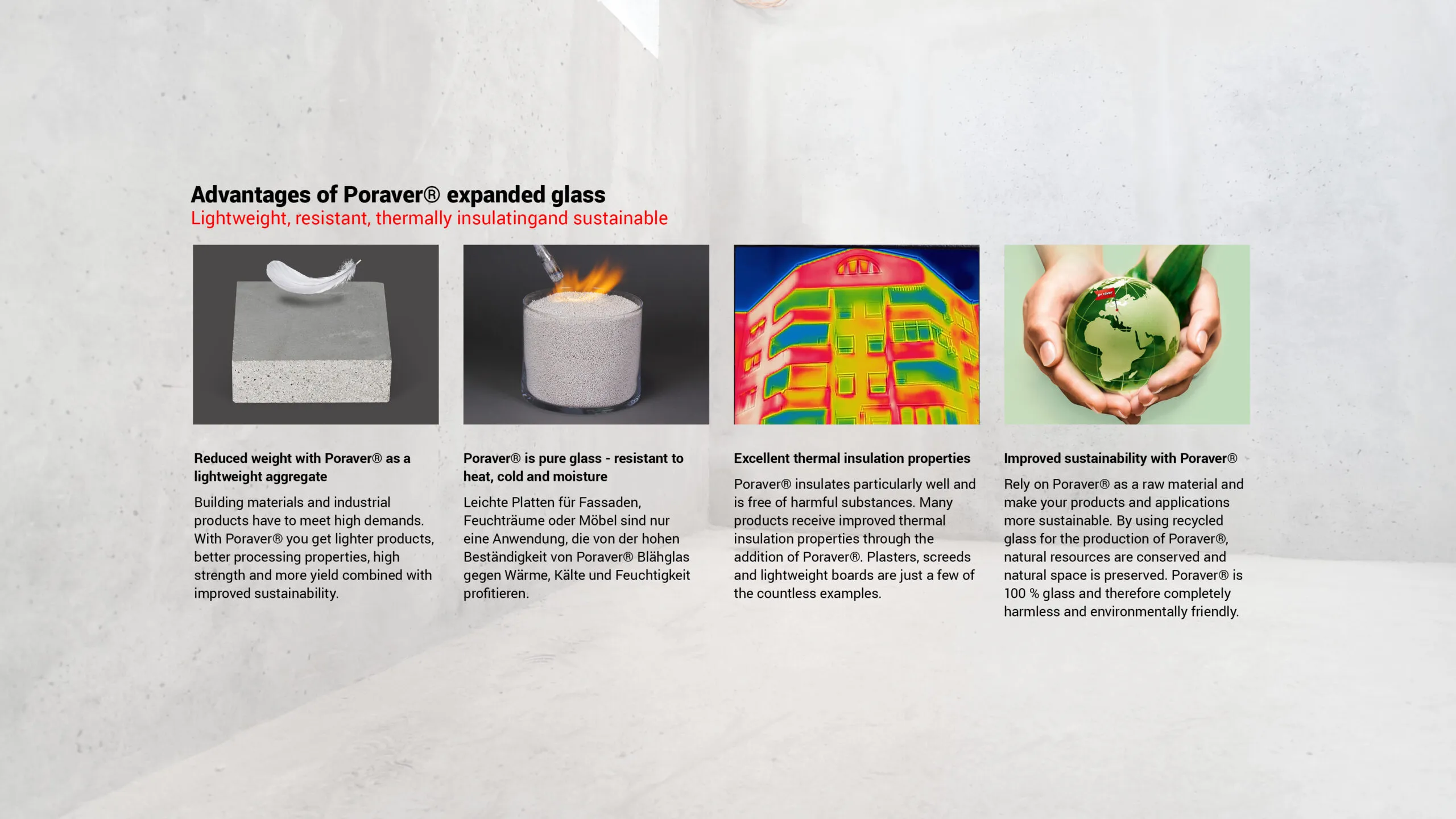

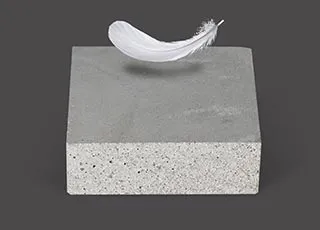

Reduced weight with Poraver® as a lightweight

aggregate

Building materials and industrial products have

to meet high demands. With Poraver® you get

lighter products, better processing properties,

high strength and more yield combined with

improved sustainability.

Poraver® is pure glass – resistant to heat, cold

and moisture

Lightweight panels for facades, damp rooms or

furniture are just one application that benefit

from the high resistance of Poraver® expanded

glass to heat, cold and moisture.

Excellent thermal insulation properties for many applications

Poraver® insulates particularly well and is

free of harmful substances. Many products

receive additionally improved thermal insulation

properties through the addition of Poraver®.

Plasters, screeds and lightweight boards are just

a few of the countless examples.

Improved sustainability with Poraver® as a raw material

Rely on Poraver® as a raw material and make your products and applications more sustainable.

By using recycled glass for the production of

Poraver®, natural resources are conserved and

natural space is preserved. Poraver® is 100 %

glass and therefore completely harmless and

environmentally friendly.