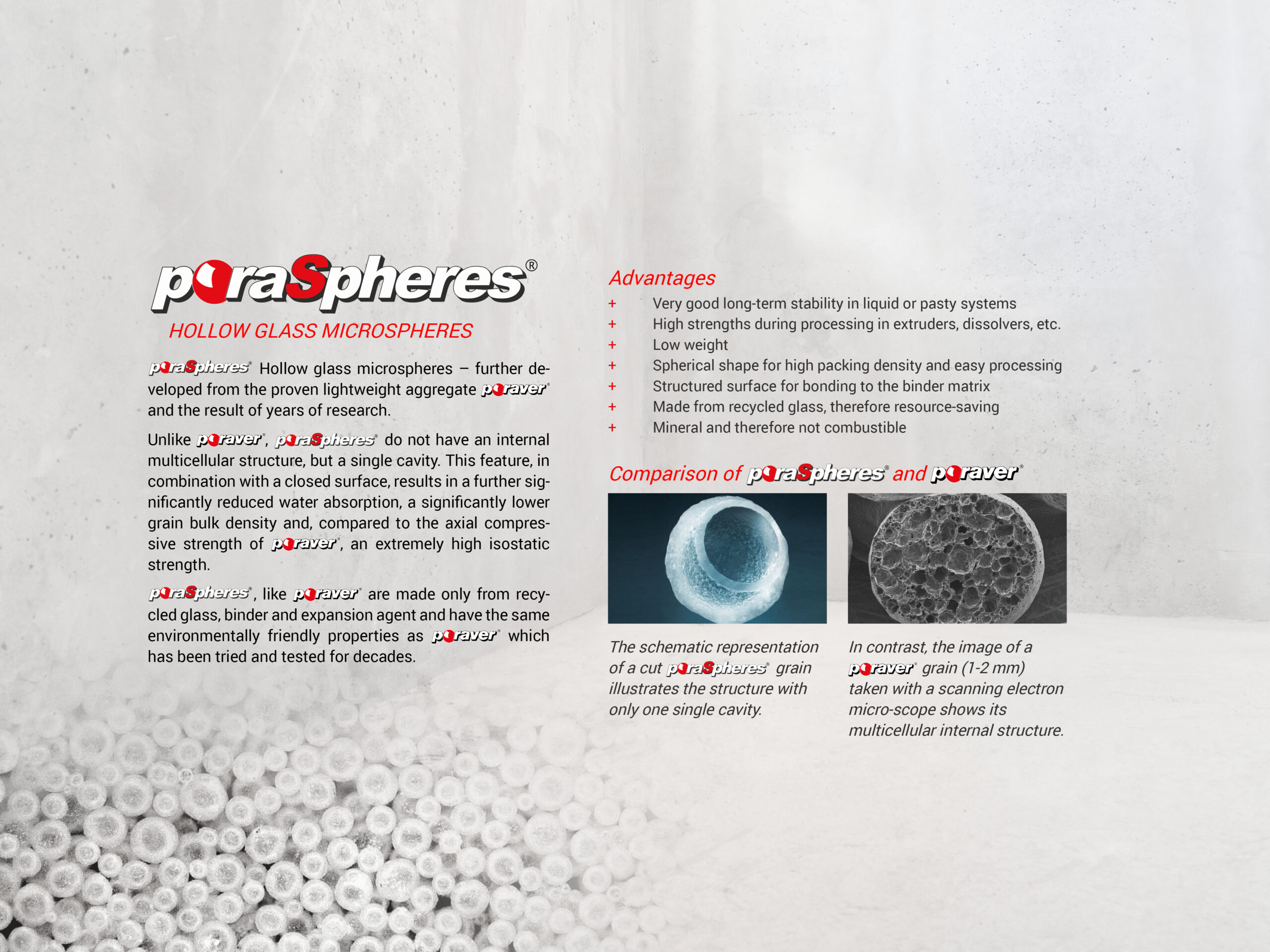

poraSpheres® Hollow glass microspheres – further devel- oped from the proven lightweight aggregate Poraver® and the result of years of research.

Unlike Poraver®, poraSpheres® do not have an internal multicellular structure, but a single cavity. This feature, in combination with a closed surface, results in a further sig- nificantly reduced water absorption, a significantly lower grain bulk density and, compared to the axial compressive strength of Poraver®, an extremely high isostatic strength.

poraSpheres®, like Poraver® are made only from recycled glass, binder and expansion agent and have the same en- vironmentally friendly properties as Poraver® which has been tried and tested for decades.

Advantages

+ Very good long-term stability in liquid or pasty systems

+ High strengths during processing in extruders, dissolvers, etc.

+ Low weight

+ Spherical shape for high packing density and easy processing

+ Structured surface for bonding to the binder matrix

+ Made from recycled glass, therefore resource-saving

+ Mineral and therefore not combustible

The schematic representation of a cut poraSperes® grain illustrates the structure with only one single cavity.

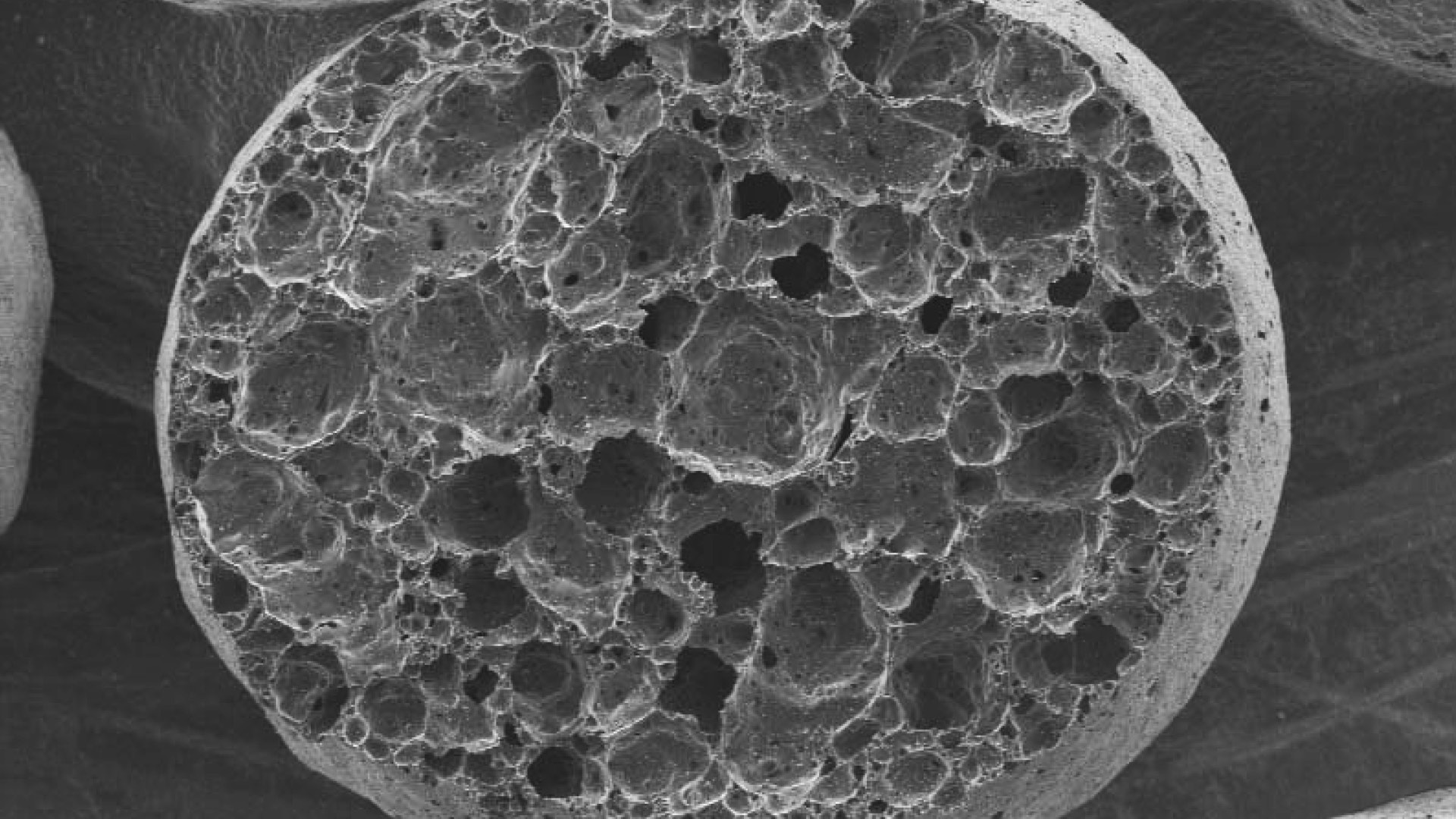

In contrast, the image of a Poraver® grain (1-2 mm) taken with a scanning electron micro-scope shows its multicellular internal structure.

In automotive engineering, mate- rials are required to have low weight combined with high strength and stiffness. Here poraSpheres® are the optimal filler. They reduce the weight of anti-drumming mats, ad- hesives and, as a component of poraComp®, also of plastics. Due to their high isostatic compressive strengths, poraSpheres® can be used in extrusion and injection mol- ding processes without being des- troyed.

Due to the reduced binder absorp- tion, poraSpheres® can be used

in 2K thermoset systems. The low density and reduced brittleness benefit applications such as polyes- ter putties, high-quality epoxy-bond- ed grouts for tiles as well as mineral casting products such as shower trays and washstands. Due to the fineness of poraSpheres® they can also be used to produce delicate decorative profiles.

poraSpheres® help to reduce water absorption, for example in self-le- veling underlayments. By using po- raSpheres® the proportion of ag- gregates can be increased without negatively affecting the consistency of the material. Due to the fine but light spheres tile adhesives become far more „creamy“.

poraSpheres® show their full strength in pasty „ready-to-use pro- ducts“. Due to the closed surface, these products can be stored for

a long time without significantly changing their viscosity.

As with Poraver® the spherical shape ensures excellent proces- sability and the textured surface enables mechanical bonding to the polymer matrix.

Typical applications are pasty tile adhesives, fire protection com- pounds, premium and effect plas- ters, sealing compounds and rein- forcing compounds for ETICS. With the finest poraSpheres® even appli- cations such as parquet adhesives and emulsion paints become pos- sible.

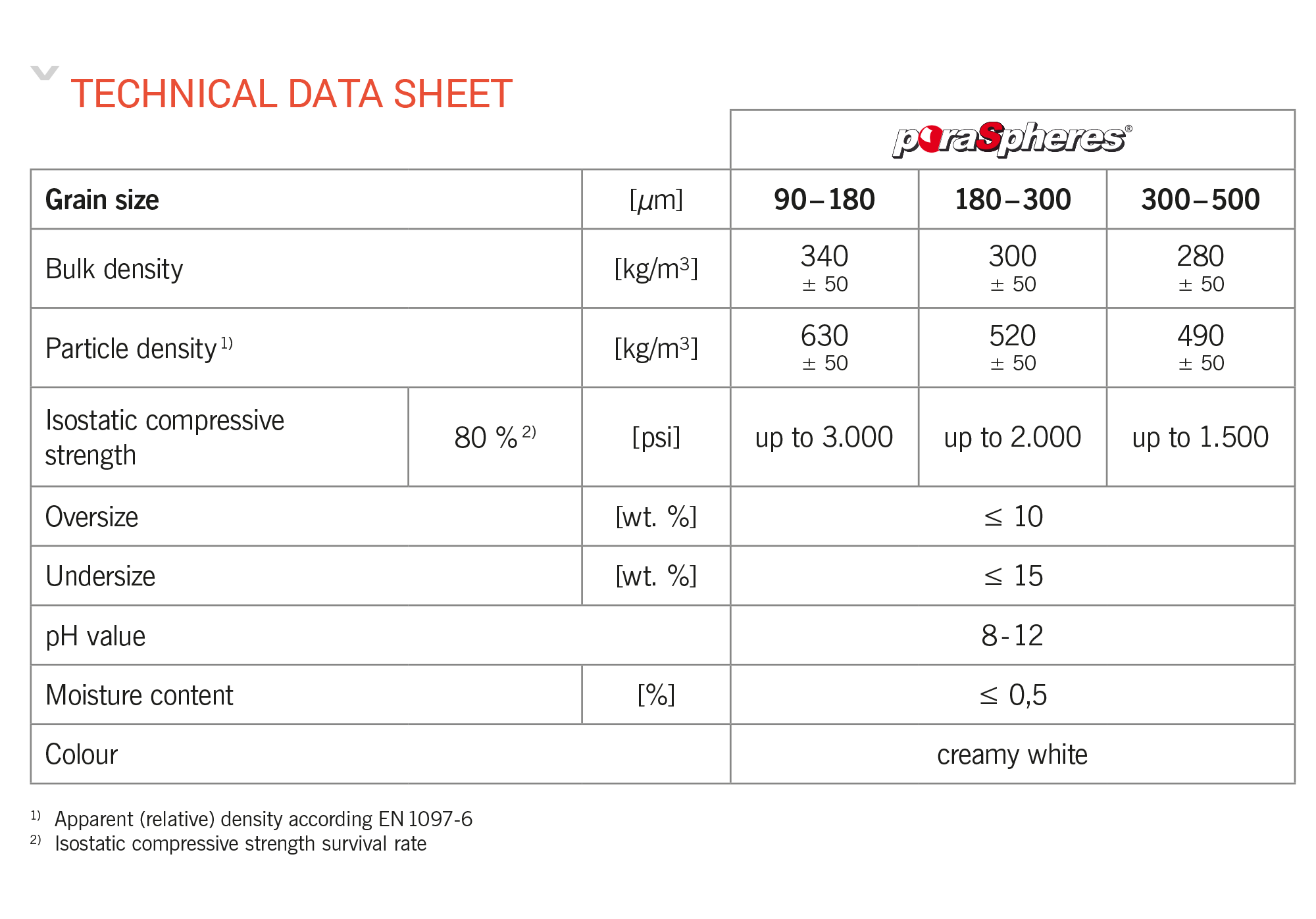

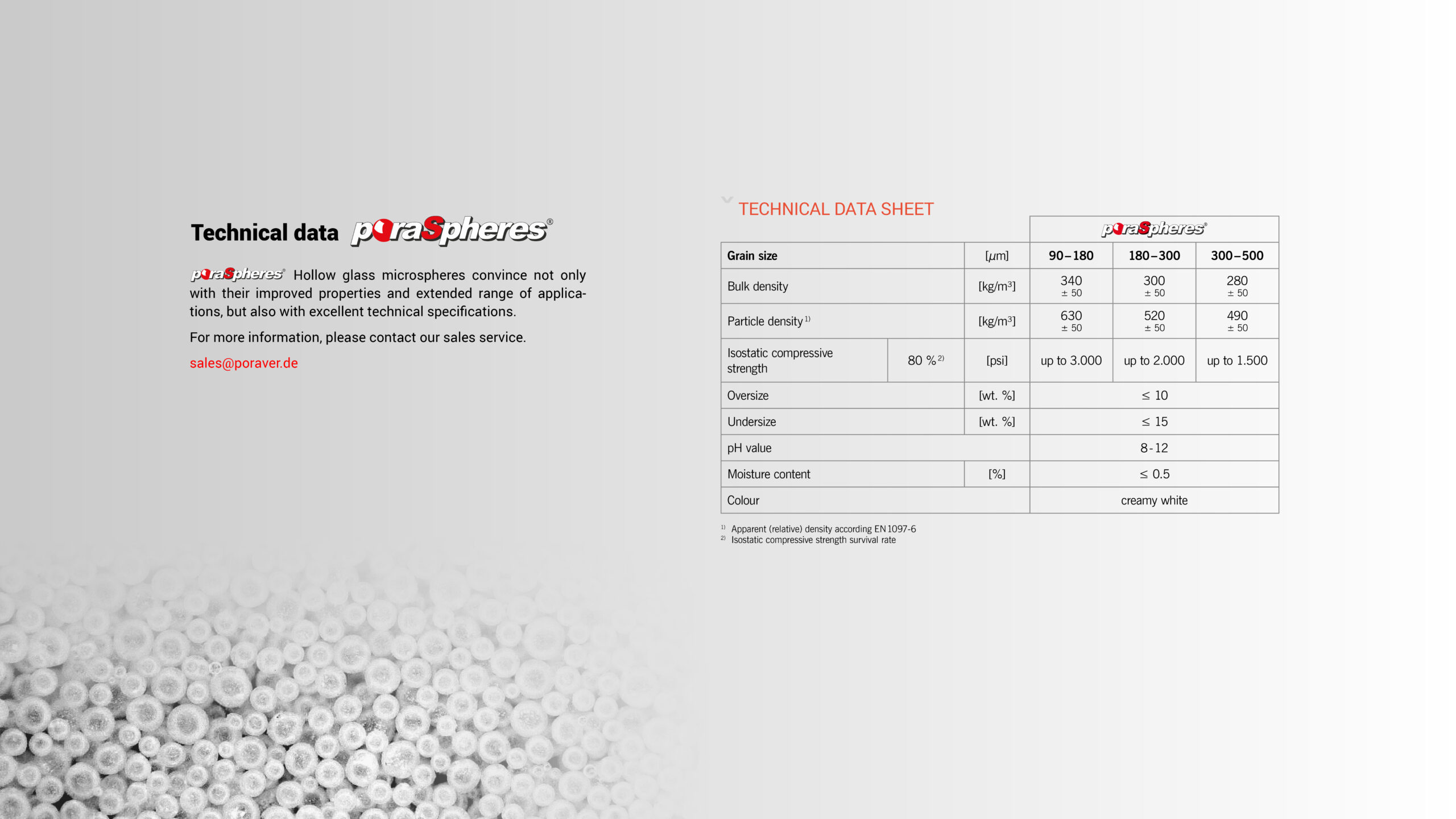

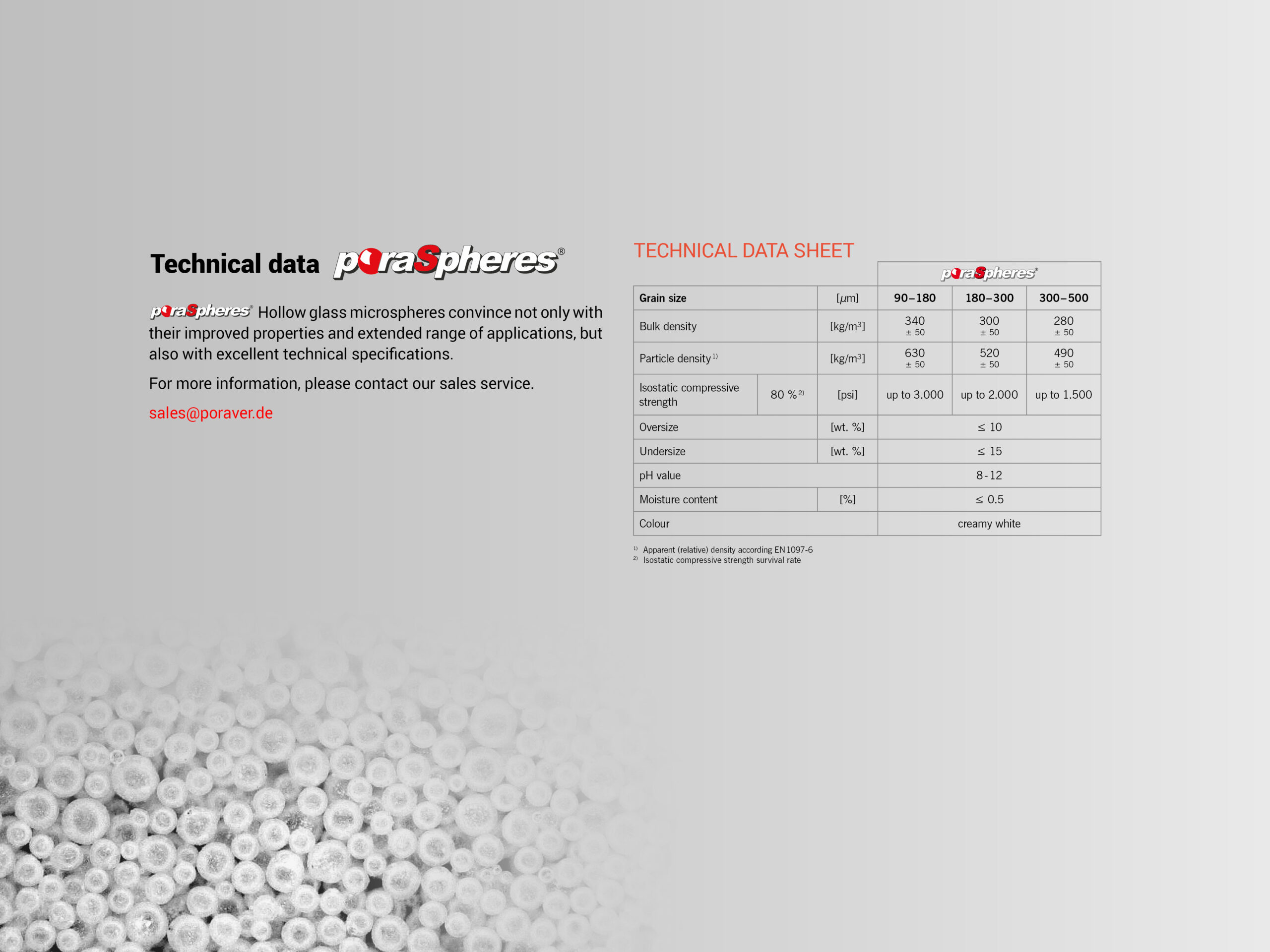

poraSpheres® Hollow glass microspheres convince not only with their improved properties and extended range of applications, but also with excellent technical specifications.

For more information, please contact our sales service.